-

What is my Research in Engineering about?

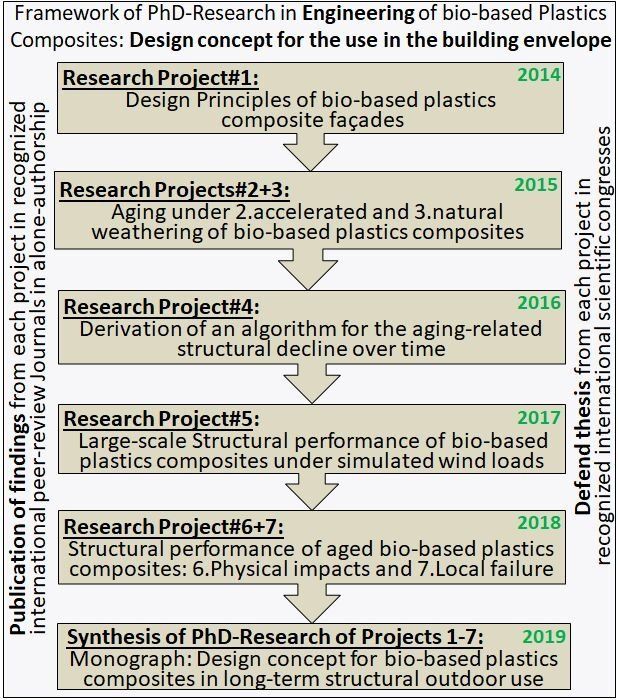

The use of bio-based plastics composites in large-scale products like in the building industry or in mass-commodities such as packaging is not yet far approached. My Doctor-related research in Engineering therefore touches on material properties under long-term structural applications and under short-term use. Both aspects are related to products which are affected by hygrothermal impacts like natural weathering or packaging in which humid contents are transported. All my studies are in the field of material sciences and application engineering which consider either simulated or realistic serviceability conditions. I apply both laboratory material and product testing but also research by the use of existing empiric data from previous studies worldwide. Further methods are statistical analysis of significance for the derivation of basic rules for the behaviour of WPCs under particular impacts as well as sensitivity analysis to provoke desired material reaction under determined conditions. From such analysis it is feasible to identify insights of appropriate compound formulations for intended applications and to select the most cost-efficient compound which best meets consumer requirements.

All my engineering Doctoral projects go hand in hand with my research in economics because such novel materials must compete against existing low-price alternatives. Particularly the building industry focuses much on long-term structural performance criteria. However, in times of increasing environmental awareness such green materials gain in acceptance even though prices are comparatively higher and physical and mechanical properties are mostly inferior. My engineering-related Doctoral research intends to support the market penetration of bio-based plastics composites in order to make them competitive against low price petrochemical plastics. This will be feasible once the technical performance and durability of WPC is sufficiently and reliably high for use in packaging and building products.

-

Research Project #1: 2016-2017_Quantification concept for application-oriented performance of bio-based plastics composites used outdoor

Discipline:

Engineering / Material Sciences

Hypothesis: The long-term structural performance of novel bio-based plastics composites is quantifiable by the application of norms and standards in the field of civil engineering.

Method:

Derivation of a design-method by meta-analysis after comprehensive literature research about building materials in long-term structural applications. Standardization aspects in engineering were adapted to bio-based plastics composites to be used in the building envelope. Findings from the Research Project no.2 in the ongoing Doctoral-research in Economics were applied accordingly.

Findings:

Material performance characteristics from mechanical testing should become transferred in the aged state in order to receive a design value for the strength calculation of potential WPC cladding used in the building envelope. The calculation method is derived from EUROCODE 1. Critical issue will be the quantification of WPC ageing.

Progress:

The elaborated design concept will enable a more application-oriented product development in the field of WPC and this will lead to higher acceptance of such novel bio-regenerative materials in the building industry.

Dissemination:

4. Working Paper No4: „Kunststoffhaltige Fassadensysteme“

Next steps:

Analysis of empiric data about long-term structural performance and ageing behaviour of bio-based plastics composites in outdoor use.

-

Research Project #2: 2016-2017_Meta-analysis on empiric data from artificial weathering test of bio-based plastics composites

Discipline:

Engineering / Material Sciences

Hypothesis:

Bio-based plastics composites react sensitive on hygrothermal impact in outdoor weathering. This property-degrading effect is quantifiable.

Method:

Comprehensive literature review on empiric data derived from material studies worldwide. Subsequent meta-analysis and derivation of principles to describe material degradation over time under artificial weathering.

Findings:

Artificial weathering in climate chambers degrades both the wood fibres and plastics matrix. Degradation is a function of time but depends strongly on the compound formulation. A general ageing coefficient valid for all kind of WPC is feasible to derive but less economic since virgin strength values go down by 75% when transferred to a global design value.

Progress:

Strength properties like MOR and MOE degrade by some 25% which makes the long-term design calculation of WPC facades feasible. However, artificial weathering is appropriate for quantification of compound quality but obviously less for real-life strength calculations in practice.

Dissemination:

Next steps:

Now that ageing in artificial conditions is quantified a more application-oriented approach should be investigated like large-scale performance tests of WPC used in facades and long-term outdoor testing under natural weathering to quantify the relationship between artificial and natural conditions.

-

Research Project #3: 2017-2018_Meta-analysis on the analogy of natural and artificial aging of bio-based plastics composites in outdoor use

Discipline:

Engineering / Material Sciences

Hypothesis:

The ageing of bio-based plastics composites is mainly due to interfacial degradation between fibres and matrix. This effect is similar between artificial and natural weathering but approaching differently in terms of intensity and time.

Method:

Comprehensive literature research and meta-analysis of empiric data about material ageing.

Findings:

The empiric data reveal a different approach of ageing. The degree of structural degradation of WPC under natural weathering can be derived from artificial weathering testing.

Progress:

Quality between fibres and matrix is limiting factor for a long-term structural performance of WPC facades. MAPP and lubricants improve durability significantly, however since such promoters are costly the development of compounds should consider the application thoroughly.

Dissemination:

Further disseminations planed.

Next steps:

Development of an algorithm-based approach for quantifying the structural properties of aged bio-based plastics composites used in outdoor applications.

-

Research Project #4: 2017-2018_An algorithm-based approach for the quantification of WPC aging over time

Discipline:

Engineering / Material Sciences

Hypothesis:

WPC aging under natural weathering is quantifiable and calculable from empiric data received by artificial weathering. The relationship between artificially and naturally aged WPC is described by an acceleration factor which not significantly differs for divers compound formulations.

Method:

Assessment of empiric data from WPC research worldwide and calculation of an algorithm by means of quantitative methods like factorial and sensitivity analysis.

Findings:

The acceleration factor between artificially and naturally aged WPC is approximately 7.35 for diverse fibre loadings and plastics matrices. Hence, aging under both conditions follows a natural procedure which is subject to basic rules.

Progress:

For the application-oriented development of WPC compounds it is feasible to determine the exact compound formulation for an intended lifetime in outdoor use. This makes the compound and product development more cost efficient. Development-related material testing can be conducted in climate chambers from which the exact life time-dependent weathering duration is predictable prior to testing.

Dissemination:

2. D.Friedrich, Comparison of naturally and artificially weathered wood-polymer composites: An algorithm-based approach , Presentation at the Polymer Testing & Analysis Conference 2019, 18-19 September 2019, Düsseldorf, Germany.

Next steps:

Large-scale performance tests on bio-based plastics composite sample facades in order to know about a characteristic resistance values and the main failure mode of such cladding products.

-

Research Project #5: 2016-2017_Investigations on structural large-scale behavior of bio-based plastics composites under simulated wind suction

Discipline:

Engineering / Material Sciences

Hypothesis:

The structural large-scale application of bio-based plastics composites in facades is limited by bending strength of the profile`s material and by the pull-through resistance of the fixation mechanism.

Method:

Experimental laboratory testing under multi-sampling with competing materials such as pure plastics. Execution under guidance of ETAG034 (foil bag tests) where simulated wind suction is applied to a facade section made from 6 profiles spanned over two fields in varying dimensions.

Findings:

Structural performance of WPC-cladding under wind suction is comparable to conventional facade materials, such as fiber-cement or pure plastics. Fixation resistance was found to be the limiting factor for a WPC-facade under real-life conditions. Resistance values depend on the field-span of sub-construction and comply with usual normative requirements. The Application of WPC-facades in the building industry appears feasible and improvement of wind-resistance is mainly in the scope of fixation-withdrawal.

Progress:

Bio-based plastics composite facades can be optimized for structural applications in the building envelope. Main mode of failure is break-out of near-edge fixations.

Dissemination:

Next steps:

Research Project on structural ageing behaviour under natural weathering for the derivation of realistic conversion factor for a WPC-cladding design value.

-

Research Project #6: 2017-2018_Physico-structural laboratory testing of aged bio-based plastics composites under hygric impacts

Discipline:

Engineering / Material Sciences

Hypothesis:

The structural performance of bio-plastics composites under natural weathering depends on hygric impacts on the interface between fibres and matrix. This negatively affects physical properties which should be considered in WPC fade design.

Method:

Experimental analysis of physico-structural performance by in laboratory testing for water uptake, density, impact strength and bending resistance of naturally aged WPC specimens.

Findings:

Structural performance of bio-based plastics composites depends on the degree of water uptake. Density increases and impact strength worsens under approaching water impact. In saturated state impact strength and bending resistance even gain in value since water-filled pores provide stability to the compound microstructure.

Progress:

The aging-related conversion factor in structural designs of WPC facades must consider a hygro-based proportion when transferring the characteristic strength value of such facades into the design state. This proportion ins quantifiable and makes some 10%.

Dissemination:

1. D.Friedrich, Natural fibre-reinforced plastics composites: Long-term physico-structural performance in facades, Congress Proceeding and Presentation at the 3rd International Conference on Bio-Based Building Materials, June 26th - 28th 2019, University of Belfast, UK.

Next steps:

Research Project on structural aging behaviour under natural weathering for the derivation of a realistic conversion factor for a WPC-cladding design value.

-

Research Project #7: 2017-2018_Local failure investigations on fixation mechanisms of naturally weathered bio-based plastics composites

Discipline:

Engineering / Material Sciences

Hypothesis:

Local failure under wind suction is less crucial compared to bending failure because fasters are stressed at the façade`s rear side where aging progresses muss slower over time.

Method:

Experimental laboratory testing of naturally aged bio-based plastics composites specimens showing different surface finishings which differently suffer from natural weathering. Testing for pull-though resistance and bending strength in length- and crosswise fibre direction. Derivation of basic knowledge about the long-term punctual and structural behaviour of WPC facades.

Findings:

Punctual strength in lengthwise direction is 25% more than crosswise. Also ageing of punctual fixating mechanisms is less crucial because stressed material is on the protected rear side of WPC panels. Fixations close to panel edges show significantly lower resistance values due to edge-cracking failures. However, covered edges are less susceptible for aging due to an effective UV-protection.

Progress:

Bending strength is a less appropriate indicatior for the assessment of long-term structural performance of WPC outdoors. The long-term structural performance is better than initially assumed because fixation mechanisms are less degraded by natural weathering. A design value for WPC facades should consider the punctual fixation strengths and less bending strength of the panel itself.

Dissemination:

1. D.Friedrich, Effects from natural weathering on long-term structural performance of wood-polymer composites cladding in the building envelope, Journal of Building Engineering.

Further disseminations planed.

Next steps:

Synthesis of all 7 research projects and proposal for an effective design concept for novel bio-based plastics composites facades ad the monographic output of the overall Doctoral research.

-

Research Project #8: 2019-_Effects from wood-fibers in plastics in the physical performance of windows

Discipline:

Engineering / Material Sciences

Hypothesis:

By adding wood fibers tothe PVC-plastics matrix of extruded window profiles the energy consumption of buildings can be improved due to lower heat transfer coefficient and lower thermal conductivity of the window.

Method:

Case study on the expected lambda-value of PVC-based WPC with varying wood-content from 0% to 80%. Sensitivity analysis for reference compounds and expected U-values for windows using reported data from publications and calculations for selected geometries and indoor climates.

Findings:

The lambda-values decrease with increasing wood-content leading to an improvement of heat transfer coefficient by 10% when 80% fibers are imbedded. This significantly keeps indoor-temperatures higher and prevents the wall-surface from mold growth. However, if too many wood fibers are embedded then the energy storage capacity of the profiles gets worsened. Hence, the optimal share of fibers is 40%-45% leading to the highest storage capacity which is 30% more compared to a profile without any fibers, hence purely PVC-based.

Progress:

WPC to be used for window profiles is a effective means of improving indor climates and saving energy of a building. Over the lifetime of the windows in buildings (i.e. approx. 30 years) this leads to monetary savings and this effect becomes even more pronounced under expected increases of energy costs in the future. PVC-windows can be greened by wood-fibers which in the optimal case is 40% content helping to releave scarce crude oil resources and to ease energy costs.

Dissemination:

1. D.Friedrich, Using PVC-based wood-plastic composites in window frames – studying performance and benefits, Profiles 2019: Proceedings of the international conference on plastic profiles for construction applications. Nov. 11th. Cologne, Germany.

2. D. Friedrich, D. Apartment Building with Wood-Polymer Windows: Case Study within COST RESTORE WG4. In: Lollini, R., Pasut, W. et al. Regenerative technologies for the indoor environment: Inspirational guidelines for practitioners. COST Action CA16114 RESTORE - Working Group Four Report. ISBN 978-3-9504607-7-3, 2020.

Next steps:

Investigations on the thermal properties of WPC used in building facades and designed for 3-dimensional shaped elements.

-

Research Project #9: 2020-2022_Effects from post-heating of Wood-Polymer Composites (WPC) on Hygro-Physical Properties to produce Thermoformed Facade Elements

Discipline:

Engineering / Material Sciences

Hypothesis:

Hot-pressing of Wood-Plastic Composites as means of industrial large-scale manufacturing method is feasible with positive effect on physical material properties decisive for application in the building envelope.

Method:

Literature review on divers Wood-Polymer compounds in the scope of physical-property testing. Sensitivity analysis researching how material behaviour changes depending on pressing temperature, duration and pressure.

Findings:

Post-heating and pressing leads to optimized properties as higher resistance to natural weathering since wood-fibre encapsulation in the polymer-matrix gets improved and density rises. Water uptake is expended to decrease and contact angles increase as indicator for higher ageing resistance.

Progress:

If WPC`s properties become better by post-processual heating and pressing the manufacture of large-scale thermoformed WPC-facades is value-enhancing and promises a potentially favourable field of application for WPC-Compounds.

Dissemination:

1. D. Friedrich. Thermoplastic moulding of Wood-Polymer Composites (WPC): A review on physical and mechanical behaviour under hot-pressing technique. Composite Structures 262 (2021), 113649.

2. D. Friedrich. Post-process hot-pressing of wood-polymer composites: Effects on physical properties. Journal of Building Engineering 46 (2021), 103818.

Next steps:

Post-processual heating and pressing of WPCs should be investigated under aspects of mechanical properties decisive in the building envelope.

-

Research Project #10: 2020-2022_Effects from post-heating of Wood-Polymer Composites (WPC) on Mechanical Properties to produce Thermoformed Facade Elements

Discipline:

Engineering / Material Sciences

Hypothesis:

Hot-pressing of Wood-Plastic Composites as means of industrial large-scale manufacturing method is feasible with positive effect on mechanical material properties decisive for application in the building envelope.

Method:

Literature review on divers Wood-Polymer compounds in the scope of mechanical-property testing. Sensitivity analysis researching how material behaviour changes depending on pressing temperature, duration and pressure.

Findings:

Post-heating and pressing leads to optimized properties as higher bending and impact strength since wood-fibre encapsulation in the polymer-matrix gets improved and density rises. Also is it expected that withdrawal of fasteners in the enhanced material is higher which supports the application in facades.

Progress:

If WPC`s properties become better by post-processual heating and pressing the manufacture of large-scale thermoformed WPC-facades is value-enhancing and promises a potentially favourable field of application for WPC-Compounds.

Dissemination:

D. Friedrich, Change in key mechanical properties from postprocess hot pressing of commercial wood‑plastic composites with different fibre contents, Polymer Bulletin (2022).

Next steps:

Post-processual heating and pressing of WPCs should be investigated under aspects of thermos-physical properties decisive in the building envelope.

-

Research Project #11: 2020-2022_Effects from post-heating of Wood-Polymer Composites (WPC) on Thermo-Physical Properties to produce Thermoformed Facade Elements

Discipline:

Engineering / Material Science

Hypothesis:

Hot-pressing of Wood-Plastic Composites as means of industrial large-scale manufacturing method is feasible and would support the integration of Phase-Change Materials (PCM) in thermoformed geometries. Further, post-processual heating and pressing would increase thermal coefficient and the heat flow in the night hours of the building is higher which reduces the climate loads in the building.

Method:

Literature review on divers Wood-Polymer compounds in the scope of thermo-physical property testing. Material testing on thermal insulating properties and cooling rate in order to find out how heat flow takes place in the thermoformed WPC-material.

Findings:

Post-heating and pressing leads to optimized heat flow in the material with positive effect on climate loads in the building. Also thermoforming can take more time since thermal conductivity increases.

Progress:

Buildings equipped with thermoformed WPCs in their facades and with the integration of PCMs show better physical performance and regulated indoor temperatures. This enables new potential for design on building envelopes.

Dissemination:

D. Friedrich, Thermoplastic moulding of wood-polymer composites (WPC): a review and research proposal on thermo-physical and geometric design options using hot-pressing, European Journal of Wood and Wood Products (2021).

D. Friedrich, Effects on heat storage from hot-pressing of wood-plastic composites for thermoformed climate-regulating building skins, Journal of Energy Storage (2022), 105106.

Next steps:

Post-processual heating and pressing of WPCs should be investigated under aspects of material geometric design options.

-

Research Project #12: 2020-2022_ Effects from post-heating of Wood-Polymer Composites (WPC) on Geometric Properties and Property-related Cluster Analysis for Thermoformed Facade Elements

Discipline:

Engineering / Material Sciences

Hypothesis:

Hot-pressing of Wood-Plastic Composites as means of industrial large-scale manufacturing method is feasible and allows new design options by thermoforming WPC-sheets into sculptured façade elements. Post-processual thermoforming however should be conducted under knowledge of retention forced due to memory effect of the plastic-based WPC-material.

Method:

Literature review on divers Wood-Polymer compounds in the scope of sculptured WPC under heat-impact and verification of memory-effects by property testing. Investigations on minimum bending radii and retention-forces and derivation of design-rules for thermoforming of WPCs.

Findings:

Under consideration of thermoforming-dependent geometric aspects it is feasible to create sculptured WPC-façade elements for new architectural options in WPC-facades.

Progress:

Future WPC-facades under thermoforming allow new ways of designing buildings with positive impact in indoor-climate and durability of the outer building skin.

Dissemination:

1. Additive manufacturing of post-process thermoformed wood-plastic composite cladding. Automation in Construction (2922), 104322.

2. Thermoforming of wood-plastic composites: a compolytics-approach translating combined polymer and policy analyses into industrial design principles. The International Journal of Advanced Manufacturing Technology (2023).

Next steps:

Investigation on consumer- and expert attitude towards thermoformed WPCs in the building envelope to find out which material aspects are utility-enhancing for better marketing of this new product in the building industry.

Abschlusspräsentation (28 Folien) Forschungsreihe (2020-2022):

"Thermoplastic Forming of WPC by Hot-Pressing"

Teil 1 (Folien 1-6): Potential, Material; Herstellung; Eigenschaften

Teil 2 (Folien 7-10): Literatur; Soziale Aspekte; Forschungsprinzip

Teil 3 (Folien 11-13): Material; Analysetools; Disseminationen

Teil 4 (Folien 14-16): Physikalische; Mechanische Effekt-Items

Teil 5 (Folien 17-21): Thermo-phys.; Geometrische; Soziale Items

Teil 6 (Folien 22-24): Totalmodell; Decision-Tree; Case Sampling

Teil 7 (Folien 25-28): Conclusion; Limitations&Ausblick; Literatur